additive manufacturing - the technology behind it...

Additive manufacturing, also known colloquially as 3D printing, is the collective term for a steadily growing family of different manufacturing technologies in different materials.

Additive manufacturing has its roots in the early 1980s.In contrast to conventional manufacturing processes such as milling, turning, drilling, grinding, etc., in which the desired geometry of the workpiece is formed from a certain amount and shape of a starting material, this is done in additive manufacturing, as the name suggests, through adding material.

And this is only preferred in places where it is really needed or intended.

This is the great power of additive manufacturing - after all, who would build a house by carving it out of a giant block of stone?

The process of so-called 3D printing generally consists of 3 steps:

Step 1:

Creation of a digital, three-dimensional model of the desired geometry

Step 2:

The geometry data is prepared and aligned using special software for 3D printing.

Any necessary support geometries are also calculated.

Stept 3:

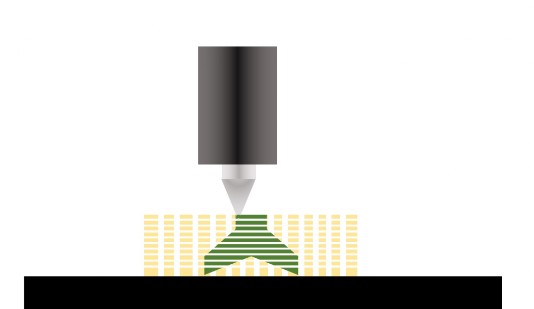

In the next step, the prepared model is virtually divided into individual sections - this process is called "slicing".

Once the so-called slicing is complete, a production program for the 3D printer is created from the geometry information defined from it.

Stept 4:

The 3D printer is equipped with the desired material. The corresponding manufacturing program is now loaded into the machine and the automatic manufacturing process is started.

Step 5:

As soon as production is complete, the component is removed from the construction platform and any existing support geometries are removed.

Depending on your wishes or requirements, further post-processing steps can be carried out here, such as inserting threaded inserts, post-processing by machining, painting, etc.

Talk to us, we would be happy to advise you.

But as with high-quality manufacturing processes, there are a few things to consider in addition to all the advantages in order to ensure reliable and high-quality production.

In order to be able to fully exploit all the possibilities and advantages of additive manufacturing, it is often necessary to rethink classic design approaches.

While it is usually expensive to remove material that is not required in "classic" machining processes such as turning or milling, it is often more expensive to add unnecessary material in the field of 3D printing. In this respect, additive manufacturing can rightly be described as a lightweight construction process.

Therefore, components that were designed for milling, for example, cannot usually be produced at lower costs in additive manufacturing, since there is usually a relatively large amount of material that is not relevant for the function of the actual component but in additive manufacturing causes additional costs.

In this respect, additive manufacturing is not in direct competition with the well-known processes, but rather complements them excellently.

Because of this property and the high level of automation inherent in all additive manufacturing processes, the advantages of these fascinating technologies can be fully exploited.